Single Girder Crane Operating Procedures and Maintenance

Single Girder Crane Operating Procedures and Maintenance

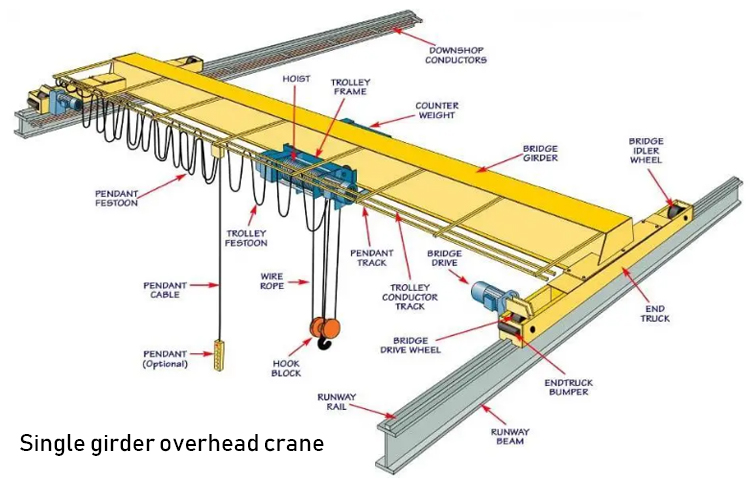

Single girder crane

First of all, the operating procedures of single girder cranes are divided into three aspects: before work, during work and after work:

Before work:

1, with a cab single girder overhead travelling crane, the driver before driving, the hook, wire rope and safety devices and other components should be inspected according to the requirements of the point inspection card, such as the discovery of anomalies, should be excluded.

2. For single girder overhead travelling crane operated on the ground, a person should be responsible for checking according to the requirements of the inspection card in each shift, and any abnormality found should be eliminated.

3、The operator must confirm that no one is on the platform or track before closing the main power supply. When the power circuit breaker is locked or there is a notice board, it should be removed by the original person concerned before closing the power supply.

Work: 1, the first time each shift lifting heavy objects or loads to reach the maximum weight, should be lifted off the ground height of 0.5 metres, re-lower the heavy objects, check the brake performance, to confirm the reliability of the normal operation.

2, the strict implementation of the "ten do not hang" system. (For details, see our other article "crane" ten do not hang "what is the content?)

3, found abnormal, should immediately stop and cut off the power supply, check the cause of timely exclusion!

After work:

1, the hook will be raised to a certain height, the car parked in the development of the position, the controller handle is placed in the "zero" position, drop the knife gate, cut off the power supply.

2、Perform daily maintenance.

3, do a good job of handover.

Single girder crane maintenance methods:

1, often check the single girder crane motor shell and the temperature of the bearing parts, motor noise, vibration with or without abnormalities.

2, the crane in the case of frequent start-up, due to the low speed caused by the ventilation and cooling capacity decline, and the current is larger, the motor temperature rise will quickly increase, should pay attention to the motor temperature rise can not exceed the upper limit value specified in the manual, in accordance with the requirements of the motor instruction manual to adjust the brake.

3, in the crane is not used very often and sealing conditions and the use of good environmental conditions, crane gearbox lubricant needs to be replaced every six months, when the use of poor environmental conditions, every quarter needs to be replaced. If you find inward water or oil surface moderate foam and determine the oil has been deteriorated, you must immediately change the oil, oil change should be strictly in accordance with the speed reducer instruction manual for the replacement of oil, be sure to avoid the mixed use of oil.

4, the daily maintenance of the reducer can refer to the manufacturer's instruction manual for maintenance, and often check the reducer foot bolt, connecting not loose.

5, crane winch set of maintenance and maintenance skills: often observe the gearbox oil window, check the oil level of lubricant is within the prescribed range, if lower than the specified oil level, must be timely replenishment of lubricant.

6, both ends of the reel bearing seat need to be filled with grease every two days, the surface of the reel and the wire rope should be coated with grease according to the situation. (The rolling bearings of the fixed and dynamic pulley block need to be replenished with grease once a month!