Slewing Jib Crane

- VOHOBOO

- Hubei, China (Mainland

- 1-50 sets lead time:30days ; 51-100 sets lead time:40days ; >100sets:to be negotiated

- 1000 Set/Sets per Month 500kg jib crane price

This machine suitable to work in the dock, warehouse, workshop etc Fixed working conditions, it can work within the 360 degrees to lift, move and materials handling.

This type machine is composed by the vertical shaft, revolivingarm, rotating shaft, hoist etc. The hoist travel with the right and left straight line on the H beam, use the hoist to lift the heavy materials. This type machine with advantages of the Simple structure, Operate convenience, Turning agile, wide working conditions.

Product Description:

Slewing jib crane is a new generation of hoisting machinery, have the character of simple structure, scientific and reasonable design, easy installation, operation and maintenance. Can be widely used in machinery manufacturing, automobile manufacturing, ship dock, iron and steel industry and other modern industrial production line, assembly line, mechanical processing of the work piece, warehouse, dock, laboratory and other occasions rigger materials operations. It is the best use equipment for enterprises to improve their working efficiency and improve working conditions.

High quality workshop jib crane Jib Crane:

Jib Crane is a kind of small and medium-sized lifting equipment with the recent development.Its unique structure, safe and reliable.With high efficiency, energy conservation, the provincial time, effort, and flexible and so on. And it can operate freely in 3D space,and it can show its superiority more especially when its working in the short-range and intensive lifting occasions.Widely used in workshops, warehouses, docks and other fixed place.

Compact Design:

The advanced design idea gives the crane light structure and excellent performance, at the same time narrows the hook operation distance in the maximum, and improves the space utilization rate effectively. So it can reduce your workshop investment costs and bring more investment returns.

Smooth, Fast Loading

The standard configuration of the crane are the trolley and crane both having step-less frequency conversion control system, with features of braked stably, accurate location, and reliable performance, which make traveling steady, positioning quick, solving the problem of swing of goods. Safer, Reliable, Using Free Maintenance Design The crane used the best technology in the whole process shows its superiority, especially in the frequent operations. The perfect braking system improves safety and reliability a lot, which can be adjusted by itself with dustproof design, and it can be used more than 1 million times. Hardening and polishing the tooth surface will make sure the crane operate without trouble.

Excellent Performance

As an important logistics equipment, if the crane is out of order, it will cause great damage. So our products always having high quality will be your best choice.

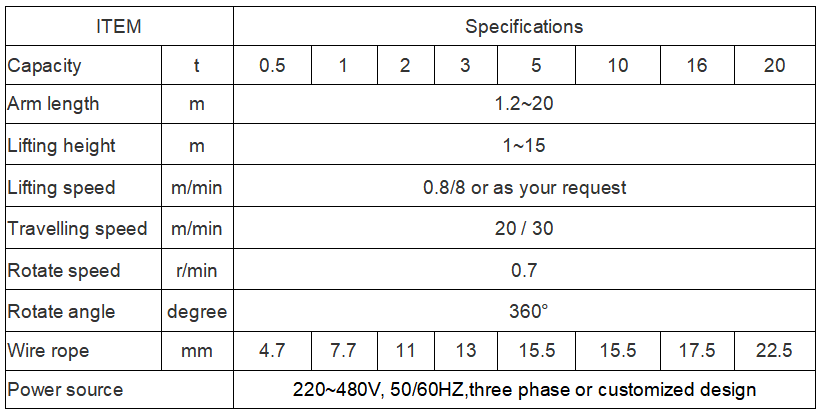

Technical parameter:

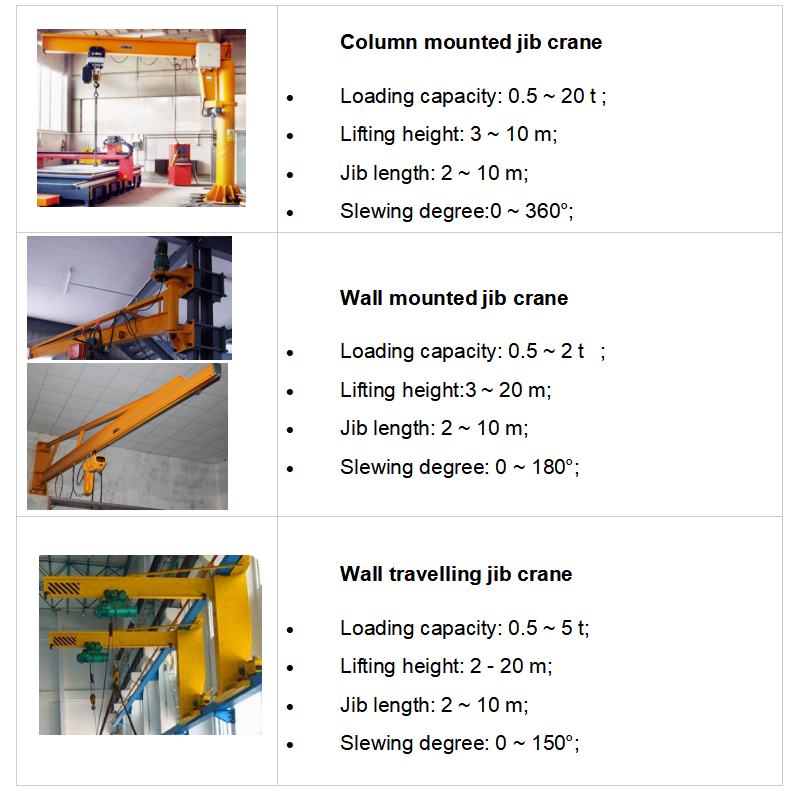

Different types jib crane for your choosing:

The structure and work principal of Slewing Arm Jib Crane

JIB crane consists 5 parts:

1. Column 2. Cantilever 3. Rotation Structure 4. Winch 5. Electric Equipments

1. Column

The column is fixed on its columns by the rotating supporting part of the crane, which is composed of the radial force and the axial force.

2. Cantilever

The cantilever is welded by the steel or box girder and the ventral arm, and its function is to support the electric or manual rotation to realize the lifting and lifting motion of the hoist.

3. Speed Reducer

The reducer is fixed in the lower part of the abdomen arm and supports the beam through the abdominal arm, so that the reducer drives the gear around the column to make a rotary motion, realizing the rotation of the crane cantilever.

4. Electrical parts

The electrical part is operated by low voltage 36V controlled voltage or wireless remote control. Controlled by the new button, the control of the hoist and the rotation of the spiral arm are respectively controlled. When it is necessary to turn at any time, the electric slip ring can be used for any rotation.

Packaging & Shipping

1. Electric parts and electric hoist are packed by high quality plywood crate to reduce distortion;

2. The beams are packed by plastic woven cloth to reduce abrasion when transport.