How to troubleshoot cranes and troubleshooting methods

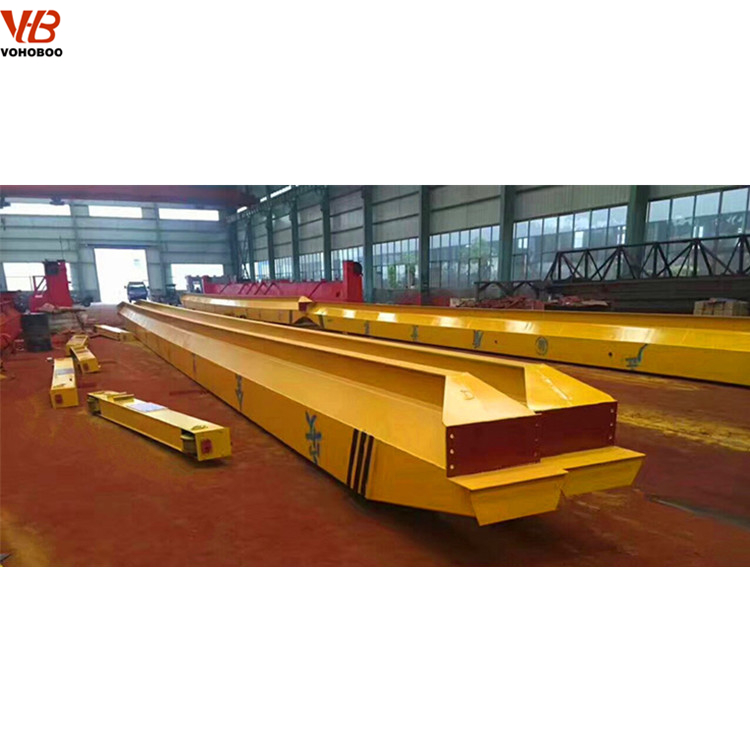

As long as the service life of the crane is long, it will inevitably cause failures. The following Vohoboo bridge double beam crane will tell you how to troubleshoot the crane and how to troubleshoot it.

1. Inspection method

First observe the index on the barometer. If the air pressure is lower than the working pressure, increase the throttle to increase the air pressure; if the air pressure is normal, you must find whether the air pipe before and after the solenoid valve is plugged in the rainy season, and whether the pipe has ruptured air leaks, causing force Insufficient air volume in the cylinder. Check whether the solenoid valve is safe and reliable. If the fault is not eliminated, remove the power take-off cylinder, remove the piston rod, replace the piston or O-ring, and remove the dirt on the inner wall of the cylinder.

When the lifting operation is completed, the power take-off switch is turned off, and the power take-off drive shaft continues to rotate to make the hydraulic pump work. Generally, there are the following reasons:

① Hold down the fork nut and loose it;

Loosen the screws on the piston rod;

③ The spring and performance of the power take-off piston rod are weakened or damaged.

2.Exclusion method

The first step is to check whether the nut holding the fork is falling off. If the nut is falling off, remove the power take-off cylinder seat, replace it with a new lock plate, and tighten the nut. If the fork is fastened to the piston rod intact, remove the power take-off cylinder back cover and check whether the screw on the piston rod is loose. If the screws come loose, tighten them again and put on the split pin. The above two items are intact and no damage. Push the piston rod by hand. If you feel that there is no free stroke and it is proved to be damaged, you must remove the cylinder seat and replace it with a new spring.