Buying skills and troubleshooting of electric wire rope hoist

The wire rope (composed of steel wire, rope core and grease) of electric hoist is relatively small in size, light in weight, stable in operation, simple in operation and easy to learn, and various in variety. Wire rope electric hoist belongs to special lifting equipment, and has the advantages of compact structure, light weight, small size, strong generality of parts, and convenient operation. In use, it is absolutely forbidden to use in the environment that is not allowed, and under the rated load and the rated closing times per hour (120 times). Its application range is also very wide, it can generally be used in mines, docks, shops or power stations, lumberyards, warehouses.

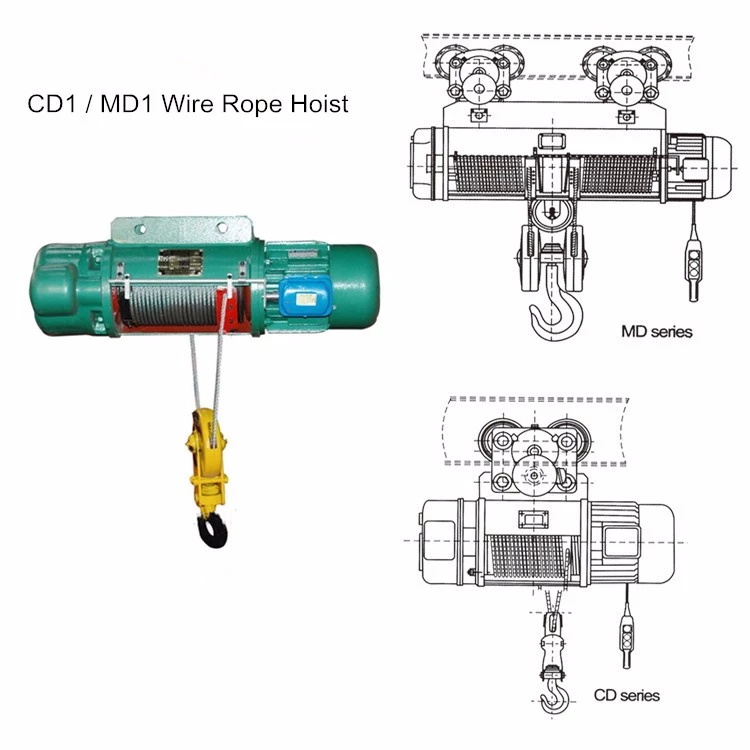

Components

Wire ropes (composed of steel wire, rope core and grease) There are many components of electric hoist, mainly including organization, reel device, coupling, reducer, limiter, etc. Equipment is generally used in mines, factories, warehouses and freight yards. For the first installation or reassembly of a wire rope electric hoist, the no-load operation should be performed first, but make sure that the components are installed and not powered. Before normal use, a static load test at 125% of the rated load and a lifting distance of about 100 mm from the ground should be performed for 10 minutes and checked for normality. It can help people complete what they can't do manually and save labor. Its lifting weight is quite large, it can lift up to ten tons of objects, and its wire rope length can be customized according to different needs. However, it should be noted that its wire rope is prone to kinking or scratching. It is necessary to always observe whether the wire rope is kinked. Once it occurs, it must be adjusted in time to prevent permanent damage. As for the scratch, the rope is easily damaged during use. The sharp part or the water chestnut is scratched, and no action is taken (pointing at the solution to the problem), which is a great hidden danger, and may be dangerous.

How to buy

Before understanding the troubleshooting, let's take a look at how to choose this problem of steel wire rope (consisting of steel wire, rope core and grease). Of course, you must have a certain understanding of the product before buying. Consult the CM company or go to the company's website to view relevant information, and then check whether the steel wire rope (consisting of steel wire, core and grease) of the product is intact when buying, it is best to go to a regular country to check the qualified merchants To buy, protect consumers' own rights and interests.

Troubleshooting

As for troubleshooting, some simple steps should still be known. It should not be overloaded during use. Once a steel wire rope (consisting of steel wire, rope core and grease) electric hoist fails, turn off the power in time to avoid danger. Wire rope electric hoist belongs to special lifting equipment, and has the advantages of compact structure, light weight, small size, strong generality of parts, and convenient operation. In use, it is absolutely forbidden to use in the environment that is not allowed, and under the rated load and the rated closing times per hour (120 times). It is necessary to clean the braking surface of the equipment from time to time, repair the brake ring in time, and the repair of the pressure spring is also very important. It must be replaced in time.