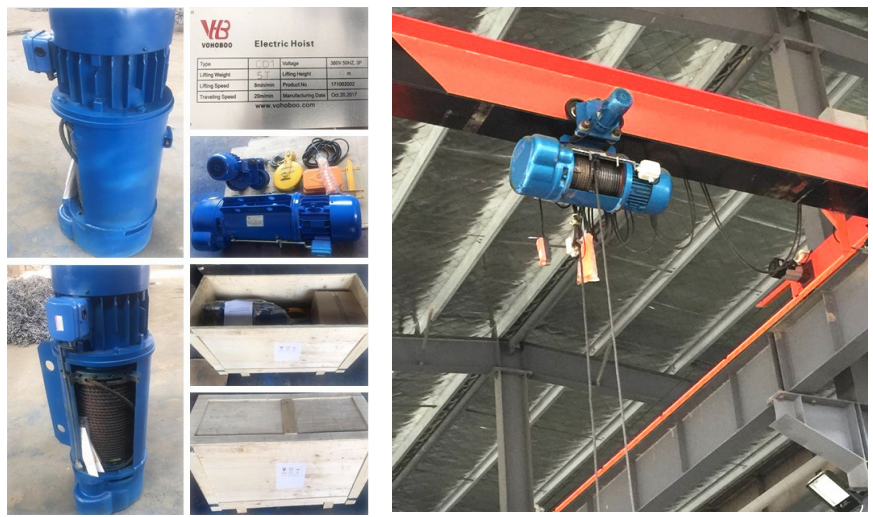

Assembly process of electric wire rope hoist

Wire rope (composed of steel wire, rope core and grease) as a lifting device, can be installed on electric single beam, manual single beam, bridge, suspension, cantilever, gantry frame with I-beam as the track In use, the requirements of the wire rope electric hoist device are self-contained (metaphors are the same, and no progress is required). Before installation, you must familiarize yourself with the installation environment, construction drawings, attention to safety matters, and detailed technical content of the website. Wire rope electric hoist belongs to special lifting equipment, and has the advantages of compact structure, light weight, small size, strong generality of parts, and convenient operation. In use, it is absolutely forbidden to use in the environment that is not allowed, and under the rated load and the rated closing times per hour (120 times).

1. Wire rope (composed of steel wire, rope core and grease)

The wire rope (consisting of steel wire, rope core and grease) electric hoist device is for aerial operation, so it is necessary to prepare safety equipment before installation, reflect on whether the equipment information meets the standard, and whether the electric hoist components are complete, and Record the consequences of introspection, carefully study the device drawings, and know the details of each device.

2. Obligation of electric hoist device for steel wire rope (composed of steel wire, rope core and grease)

When the track device is suspended, the track must be manually placed under the beam, and then the crane and the split and single beam of the electric hoist are hoisted to a position.

After paving the track, it is also necessary to make an unloading gear. The gear on the track must be installed before the hoisting crane, and the contact surfaces of the gear and the electric hoist buffer must be avoided on the same three-dimensional surface. Wire rope electric hoist belongs to special lifting equipment, and has the advantages of compact structure, light weight, small size, strong generality of parts, and convenient operation. In use, it is absolutely forbidden to use in the environment that is not allowed, and under the rated load and the rated closing times per hour (120 times).

When lifting, there must be at most two lifting points, and the binding points must be selected at both ends of the bridge.

Lift the trolley, rely on the trolley track and fix it, raise the electric hoist to a suitable height, and fix the electric hoist stop device according to the bolt (composition: head and screw) number.

3.Wire rope (composed of steel wire, rope core and grease) electric hoist device adjustment

After the installation is completed, the adjustment of the gap between the electric hoist walking wheel and the track is suspended so that the interval between the two is about 3 to 5 mm. This is an important step, which will indirectly affect the function of the electric hoist.

4.Wire rope (composed of steel wire, rope core and grease) test run of electric hoist

After the adjustment of the equipment is completed, the electric hoist of the steel wire rope (composed of steel wire, rope core and grease) is suspended from no-load test and static load experiment to ensure normal operation of the electric hoist. Wire rope electric hoist belongs to special lifting equipment, and has the advantages of compact structure, light weight, small size, strong generality of parts, and convenient operation. In use, it is absolutely forbidden to use in the environment that is not allowed, and under the rated load and the rated closing times per hour (120 times).

5. Complete the above steps (procedure) has no effect, you can deliver