Technical requirements for end fixing of electric hoist wire rope

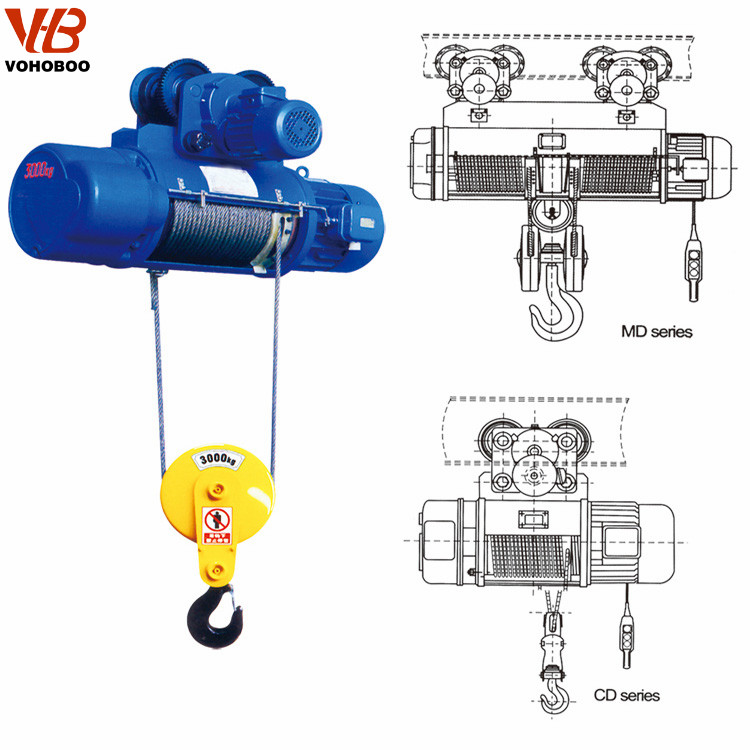

Wire rope electric hoist is a commonly used hoisting machinery, which is very convenient and quick to use. The wire rope of the wire rope electric hoist needs to be fixed at the rope end to ensure that it does not decouple or break during use. The specific technical requirements are as follows:

1. Inspection of the fixed part of the rope end.

1. Check whether the detachable wedge joints or rope clamps and other devices themselves are deformed, worn, whether there are cracks and East China, as well as broken wires and corrosion inside the device and in the rope end to ensure the reliability of the fastening of the rope end.

2. If there is obvious broken wire or corrosion in the accessories of the rope end fixing device or the rope end fixing device, the wire rope can be shortened and reinstalled on the rope end fixing device, and the length of the wire rope should be satisfied when the hook is at the lower limit. The minimum number of turns on the reel is 2 turns.

Second, the safety method of fixing the rope end of the steel wire rope.

1. Use the automatic clamping function of mechanical wedge to fix.

(1) According to JB9009-1999 "Wire Rope Electric Hoist Safety Regulations", when MD1 wire rope electric hoist uses wedge joints to fix the wire rope, it should comply with the relevant regulations of GB/T5973. When wedge joints are used, only the rope head is not loose. That is, there is no need to add a wire rope card.

(2) After the fixed end of the steel wire rope passes through the wedge, there should be more than 200mm left. The steel wire at the end of the remaining rope head should not be loosely crossed. The loose crossed part should be tightened with a thin soft iron wire to prevent the looseness of the wire rope from becoming more and more loose. A safety accident occurred due to loose steel wire rope. The penetration length is more than 4 times the diameter of the wire rope.

2. Use rope clamp to fix.

Pay attention to the following points when installing the rope clamp:

1. "U" bolts should be fastened on the tail section (short side) of the wire rope, and the wire rope clamps should not be alternately arranged on the wire rope; the distance between the rope clamps is 6-7 times the diameter of the wire rope.

2. The rope clamp should be selected according to the nominal diameter of the wire rope. The clamped wire rope should be smooth, flat and free of burrs. If the rope clamp seat has obvious bright traces of sliding friction, it should be replaced.

3. Tightening of the wire rope clamp: In order to ensure that the fixed end of the wire rope is evenly stressed, the rope clamp farthest from the wedge must not be fastened separately first. The three rope clamps should be tightened slowly at the same time, the one closest to the wedge The rope clamp should be as close as possible to the wedge. After the rope clamp is used for a period of time, the tightening state of the nut should be checked regularly.